We can therefore talk about a “partially” integrated solution.

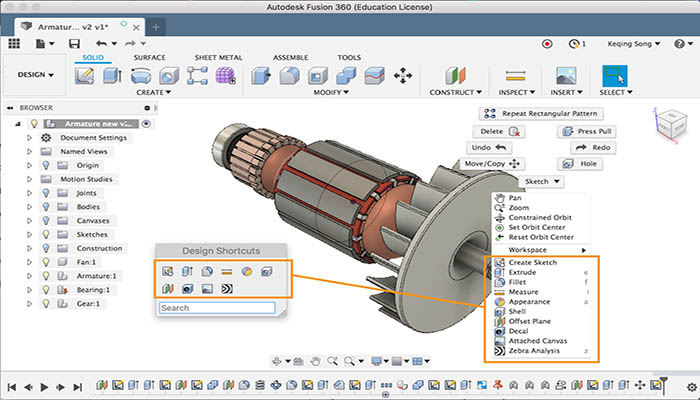

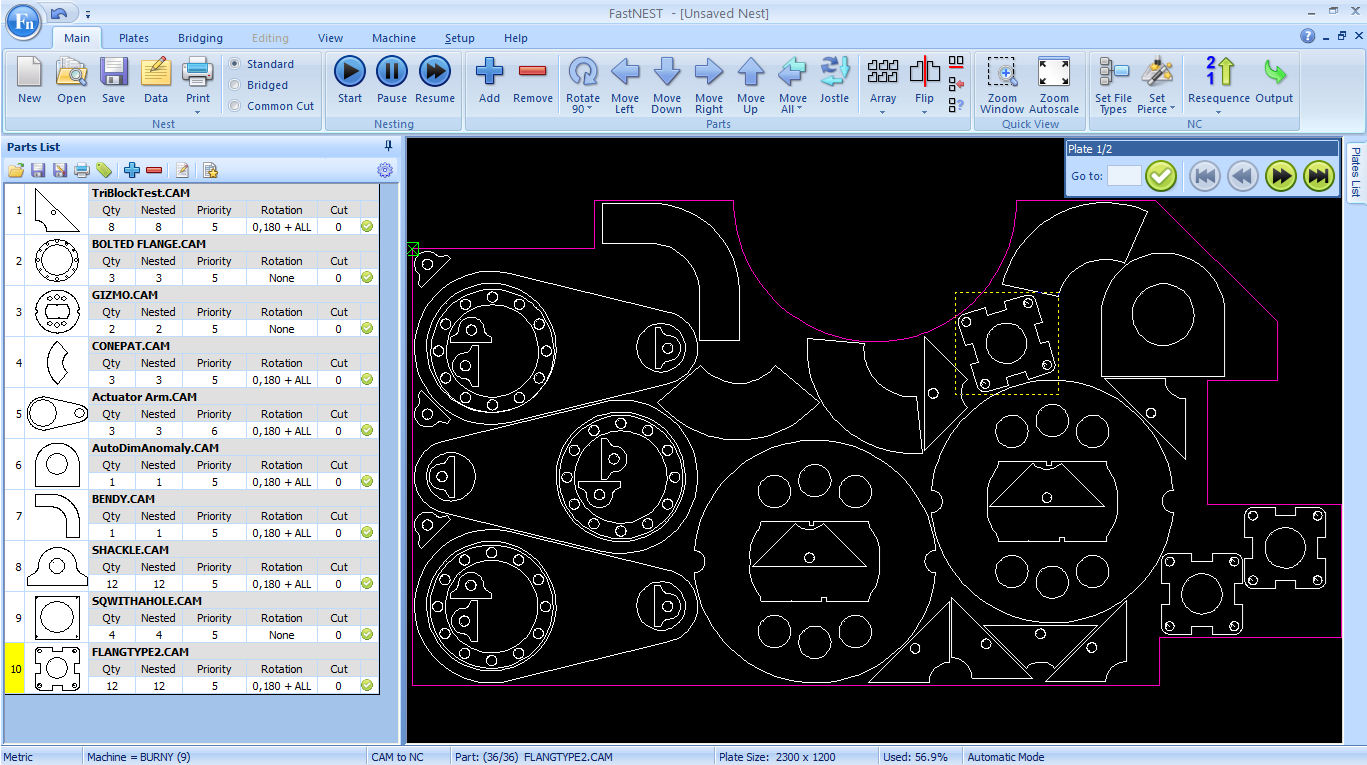

To address this situation, users tend to add a CAD solution to their CAM solution. In this case, it will be difficult for users to design their own parts to be machined or define a machining setup. only the part relating to the programming of CNC (Computer Numerical Control Machines). Some solutions only offer the Computer Aided Manufacturing option, i.e. Not all CAD and CAM solutions are created equal. What are the focal points to be taken into account? Benefits of a fully integrated CAD/CAM solution Though the added value of a CAD/CAM software is already proven, it is still necessary to choose the solution best suited to your needs, which will help you to expand your business.

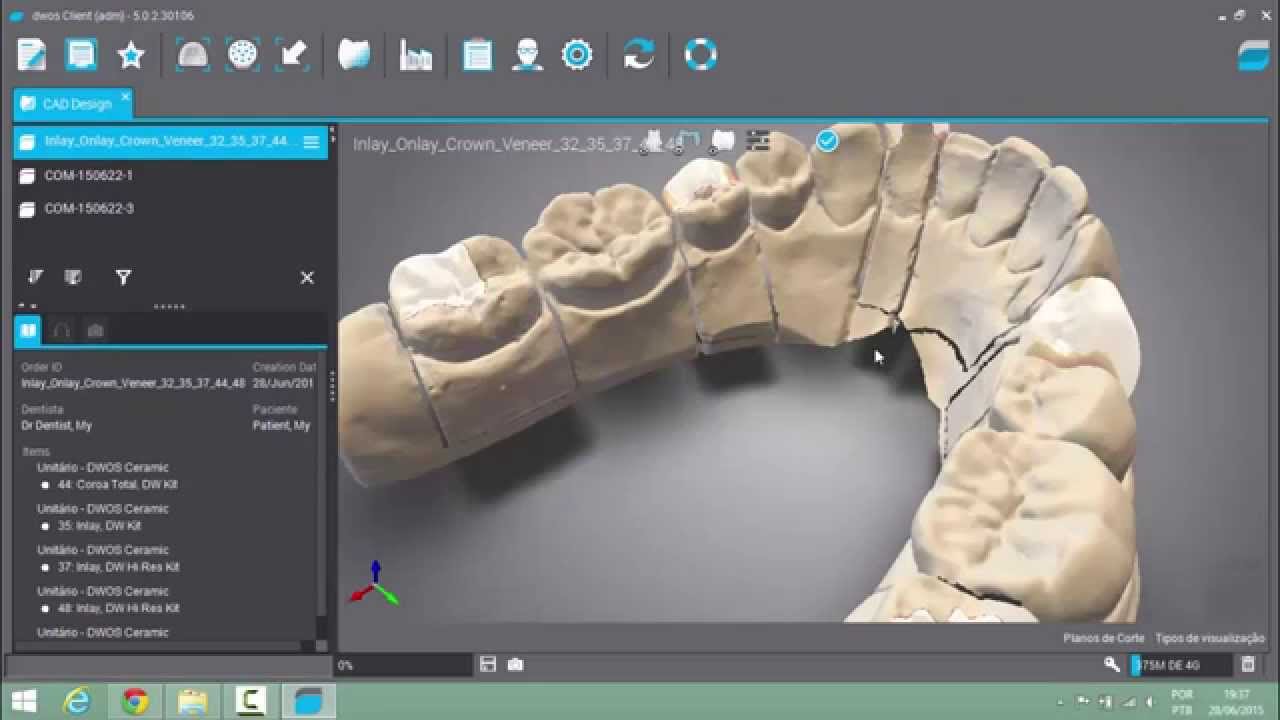

With the ability to produce more, in less time, the company can therefore go further, expand its offer, enter new markets and increase its turnover.Ĭhoosing a CAD/CAM software that supports your growth Whatever the specialization of the company, CAD/CAM becomes an ally of machines and human resources, and leads the company towards markets that were previously inaccessible due to a lack of resources. In a development logic, the acquisition of an efficient CAD/CAM is a key step for companies.

While using a manual and conversational programming “genius” may seem like a viable option, it is nonetheless unrealistic and resolutely limited for large-scale production capacity.įor many companies, equipping themselves with a CAD/CAM solution not only allows them to develop additional technical programming skills, but also represents a significant lever to be able to respond to numerous requests for tenders, which were previously declined.īetter performance, lower costs: there are many advantages to using a CAD/CAM system: Regardless of the type of business, part programming without a CAD/CAM solution, although possible, very quickly reaches a certain limit in terms of technicality and quality.

0 kommentar(er)

0 kommentar(er)